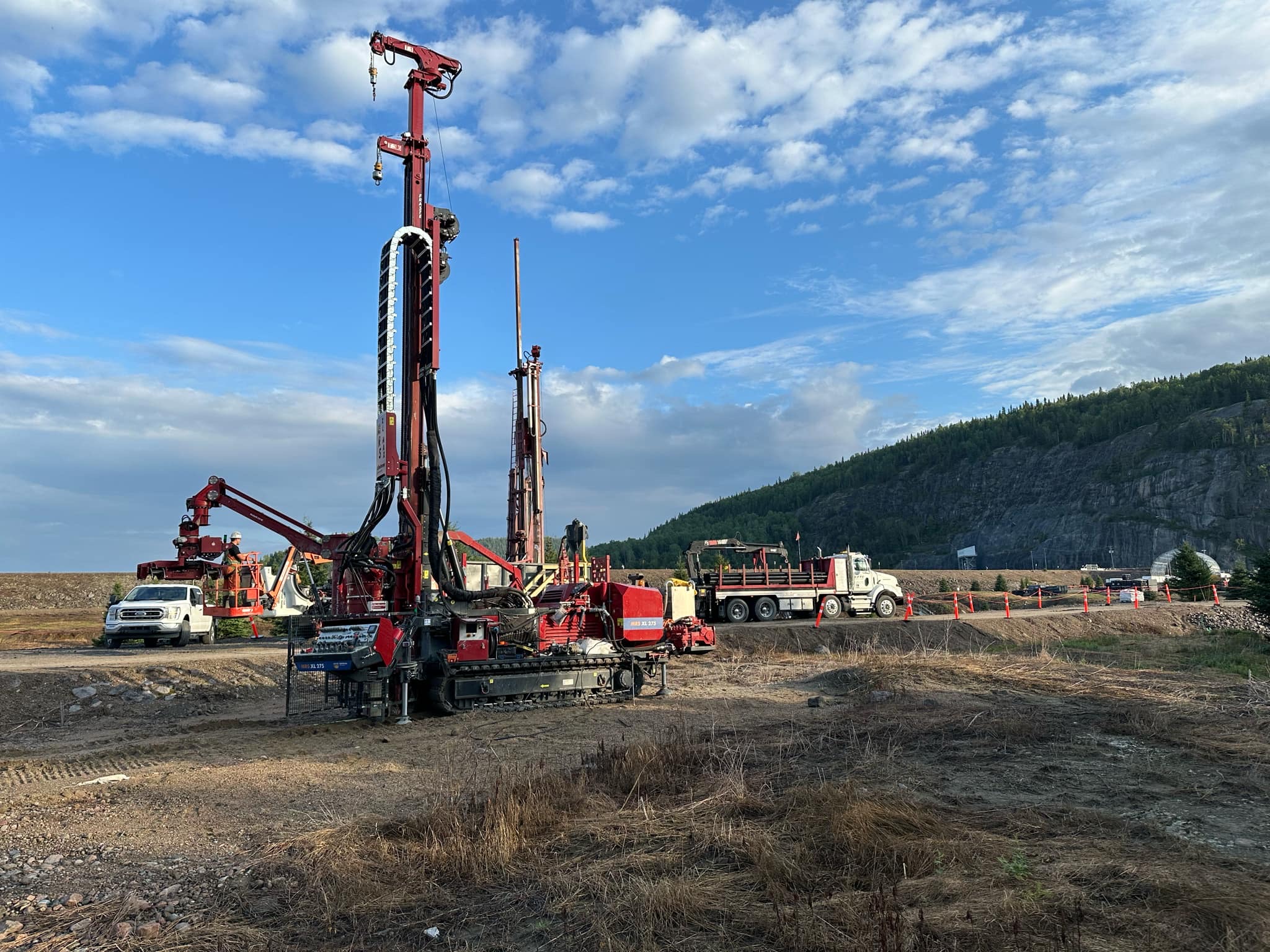

Sonic drilling is an innovative technique that uses high-frequency vibrations to penetrate geological formations.

The process is versatile and offers several uses in various sectors:

1. Geological and Mining Exploration

- Continuous and Intact Samples: Sonic drilling allows for the recovery of continuous, undisturbed soil samples, which is essential for accurate geological studies and mining exploration.

- Adaptability to Various Soil Types

- Low Deviation

-

- Drilling in Difficult Conditions: It is particularly effective in difficult conditions (sands, gravels, clays) and dense materials where other drilling methods may fail.

2. Remediation of Contaminated Sites

- Remediation: Useful for drilling the wells needed to remediate contaminated sites, particularly for injecting or extracting substances for soil treatment.

3. Geotechnics and Environment

- Waste Reduction and Environmental Protection:

- Less Drilling Waste: Sonic drilling generates less waste (cuttings) than other methods, reducing environmental impact. Additionally, the reduction in material losses means that more of the sample is well preserved for analysis.

- Reduced Impact on the Site: Sonic drilling requires smaller volumes of fluid and reduces the dispersal of materials, thus preserving the integrity of the drilling site, which is particularly important in ecologically sensitive or protected areas.

- Soil Investigations: Used to obtain precise information on soil characteristics for the construction of buildings, bridges, roads, etc.

- Monitoring Well Installations: Sonic drilling is often used to install groundwater quality monitoring wells, as it minimizes disturbance of soil layers.

- Contamination Assessment: Sonic drilling is ideal for environmental surveys since it generates precise samples to be taken for analysis of soil and groundwater contamination.

Sonic drilling is therefore an extremely useful technique in many fields, thanks to its ability to provide high-quality samples and operate efficiently in difficult soil conditions.